How does just-in-time jit relate to total quality management tqm – How does just-in-time (JIT) relate to total quality management (TQM)? This article explores the interconnectedness of these two methodologies, examining how JIT’s principles of waste reduction and continuous improvement align with TQM’s focus on customer satisfaction and quality control. By integrating JIT into TQM systems, organizations can enhance efficiency, reduce costs, and deliver superior products and services.

JIT and TQM share a common goal of eliminating waste and improving quality. JIT focuses on reducing inventory and waste in the production process, while TQM emphasizes continuous improvement and customer satisfaction. By combining these approaches, organizations can create a holistic system that drives operational excellence and customer delight.

1. Definition and Overview

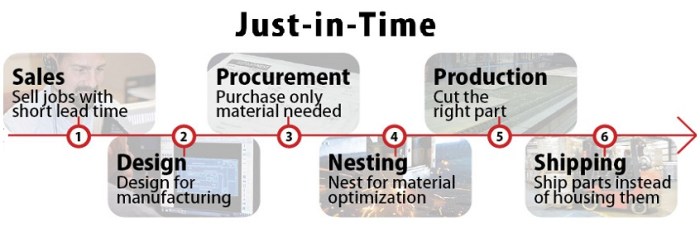

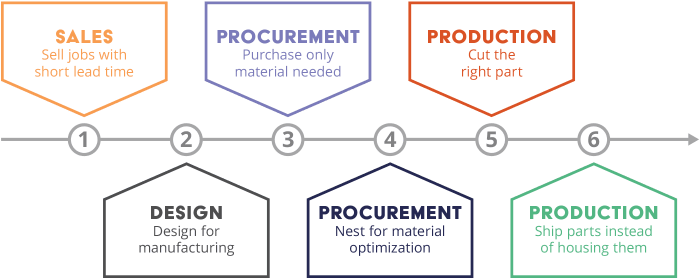

Just-in-Time (JIT) is a production and inventory management philosophy that aims to minimize waste and improve efficiency by producing and delivering goods only when they are needed. JIT principles emphasize continuous improvement, waste reduction, and the elimination of non-value-added activities.

Total Quality Management (TQM) is a comprehensive management approach that focuses on delivering high-quality products and services to customers. TQM encompasses various elements, including customer satisfaction, continuous improvement, employee involvement, and process control.

2. JIT and TQM Relationship

JIT aligns closely with the principles of TQM. Both approaches emphasize waste reduction, continuous improvement, and customer satisfaction. JIT supports TQM’s focus on quality control by minimizing inventory and reducing the likelihood of defects.

3. JIT in TQM Implementation: How Does Just-in-time Jit Relate To Total Quality Management Tqm

JIT can be effectively implemented within a TQM framework. JIT techniques such as kanban, pull systems, and single-piece flow can help reduce inventory, improve lead times, and enhance overall quality.

Benefits of integrating JIT into TQM systems include reduced waste, improved efficiency, increased customer satisfaction, and enhanced competitiveness.

4. Case Studies and Examples

Several successful case studies demonstrate the application of JIT within TQM environments. For instance, Toyota’s implementation of JIT principles has resulted in significant improvements in quality, efficiency, and customer satisfaction.

5. Future Trends and Applications

JIT and TQM continue to evolve, with emerging trends such as digitalization, lean manufacturing, and Industry 4.0. These advancements provide opportunities for further integration and optimization of JIT and TQM systems.

FAQ Insights

What are the key principles of JIT?

JIT’s key principles include reducing inventory, eliminating waste, and improving production flow.

How does JIT support TQM’s focus on customer satisfaction?

JIT helps organizations deliver products and services that meet customer requirements by reducing defects and improving quality.

What are some benefits of integrating JIT into TQM systems?

Integrating JIT into TQM systems can lead to reduced costs, improved efficiency, and enhanced customer satisfaction.